First steps into UR control

UR Basics

- Introduction

- Network

- Tools

- Inputs and Outputs

- Relative and Absolute

- Speed

- Precision

- Commands

- Rotations

- Motion and rotation

- Moving between targets

- Axes

- Tool definition

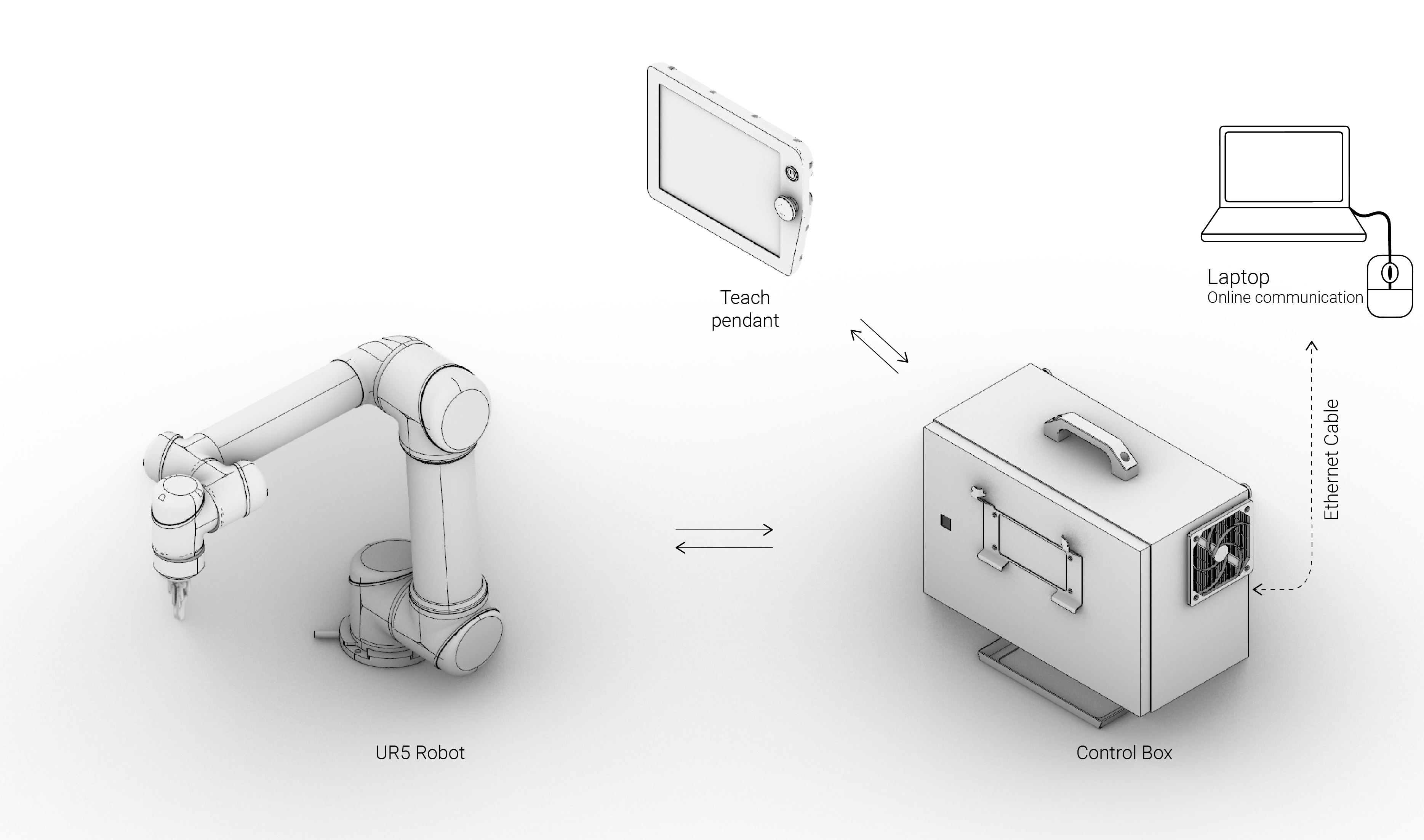

Introduction

Elements of the robot

- Robotic arm

- Controller box

- Teach pendant (Interface)

- USB Port

- ON/OFF Button

- EMERGENCY STOP

Teach pendant

Initialization

- Turn ON Robot

- Release motors

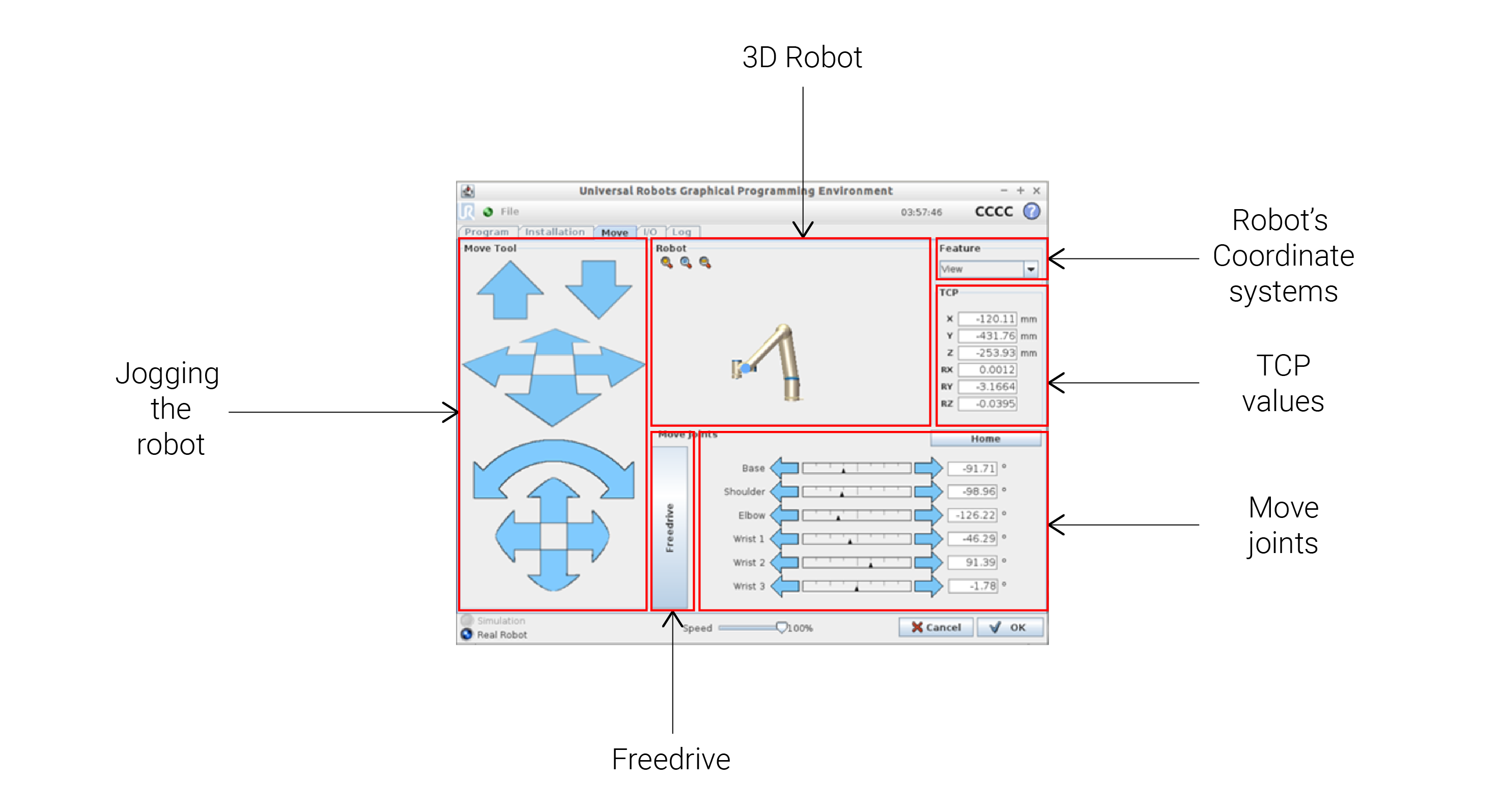

Jog robot

Different parts:

- Jogging the robot

- Robot - 3D representation

- TCP values

- Joints angular values

- HOME POSITION (0, -90, -90, -90, 90, 90)

- Free-drive + Backside button

Network

Configuration

- Connection

- Ethernet cable

- Wireless (not recommended)

- Network

- DHCP (non-static)

- Static Address

- IP Address: 192.168.0.xx

- Subnet mask: 255.255.255.0

- Connection Check: cmd promt (Win)

- ping

- ipconfig

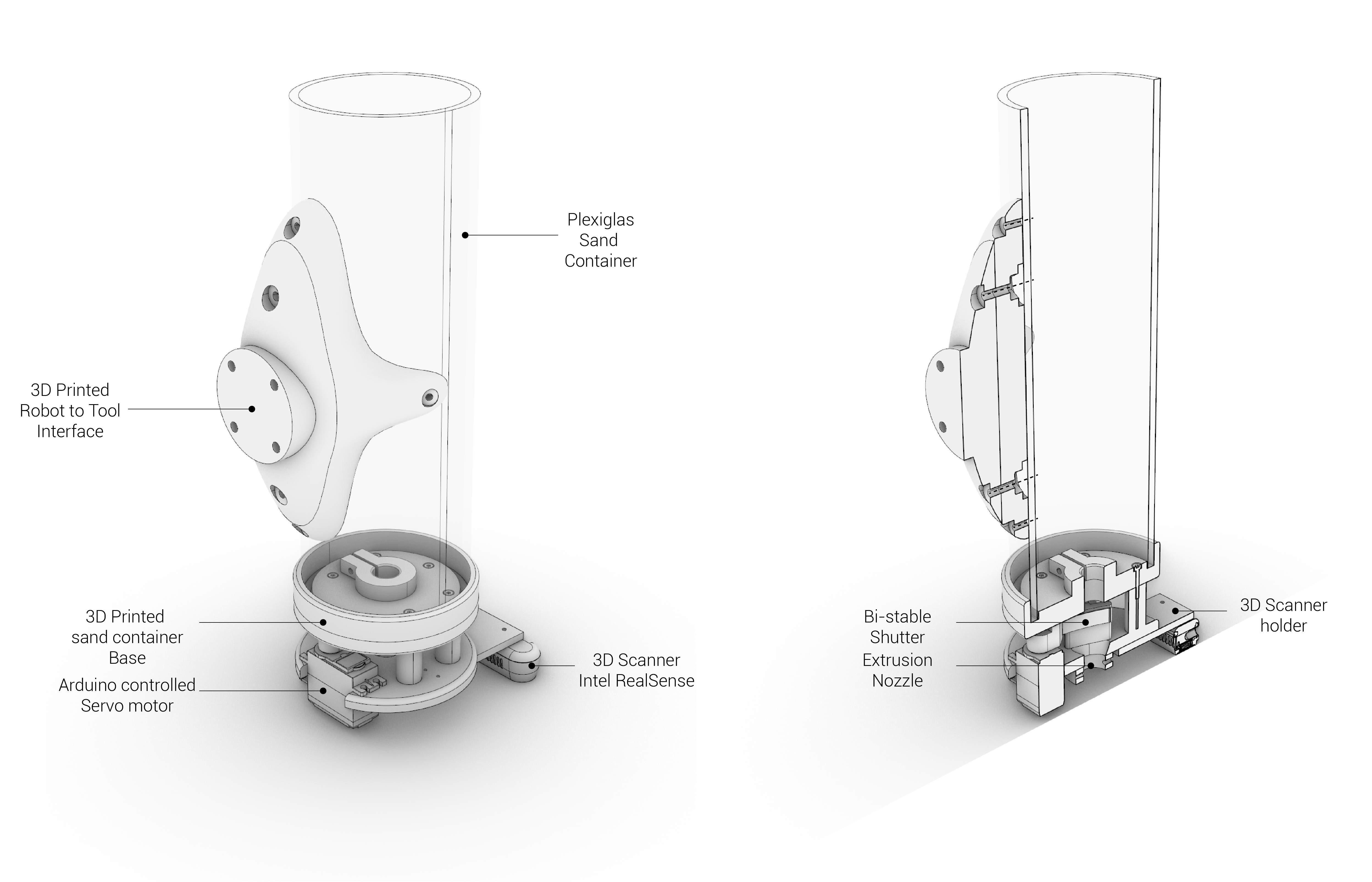

Tools

- End-effector name

- Sand extruder

- Gripper

- Pencil

- Filament extruder

- etc…

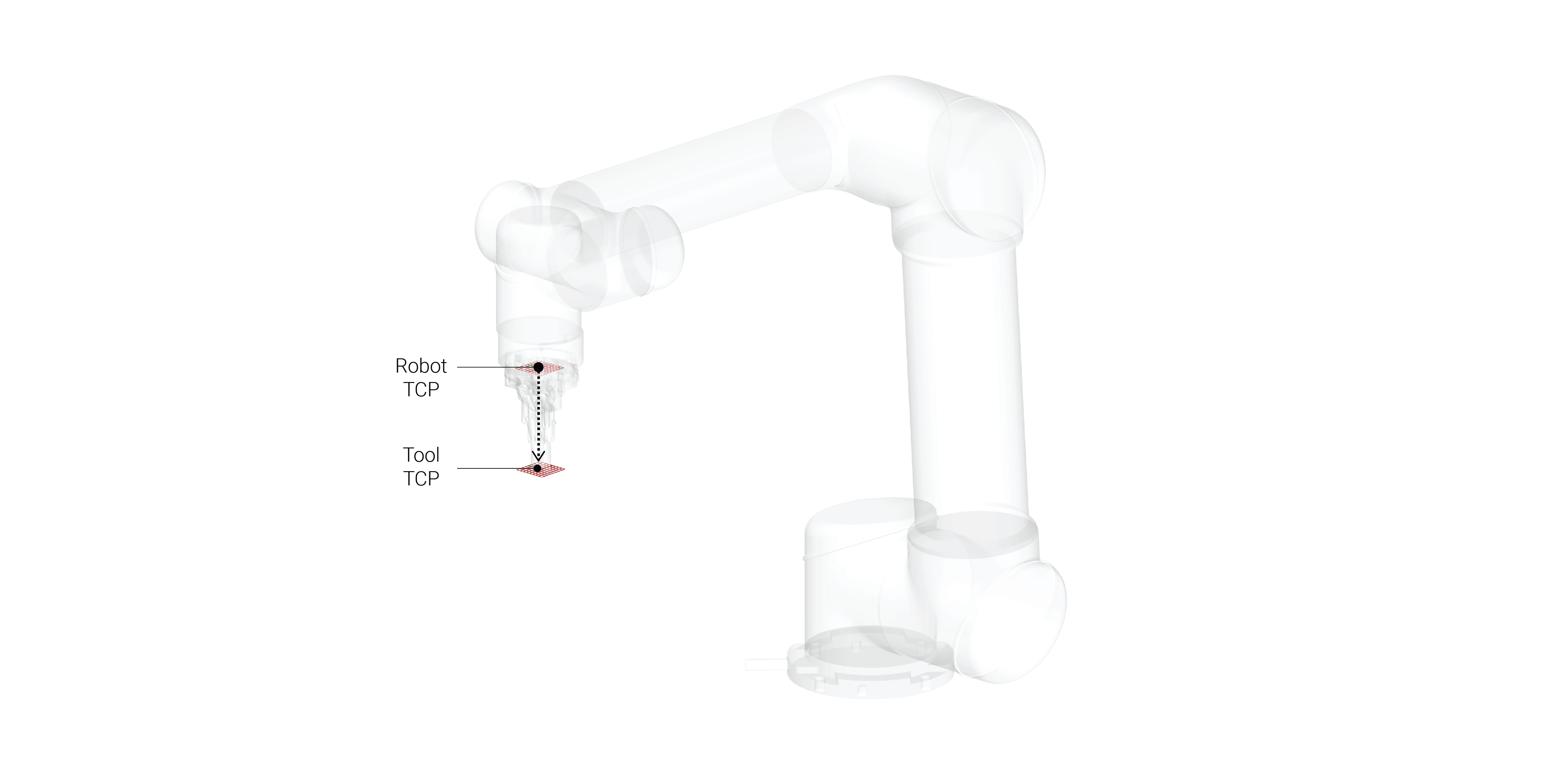

- TCP (Tool Center Point)

- Adjusted for every tool

- Weight adjustment

- Tool specific electronics

- Arduino

- Servo motor

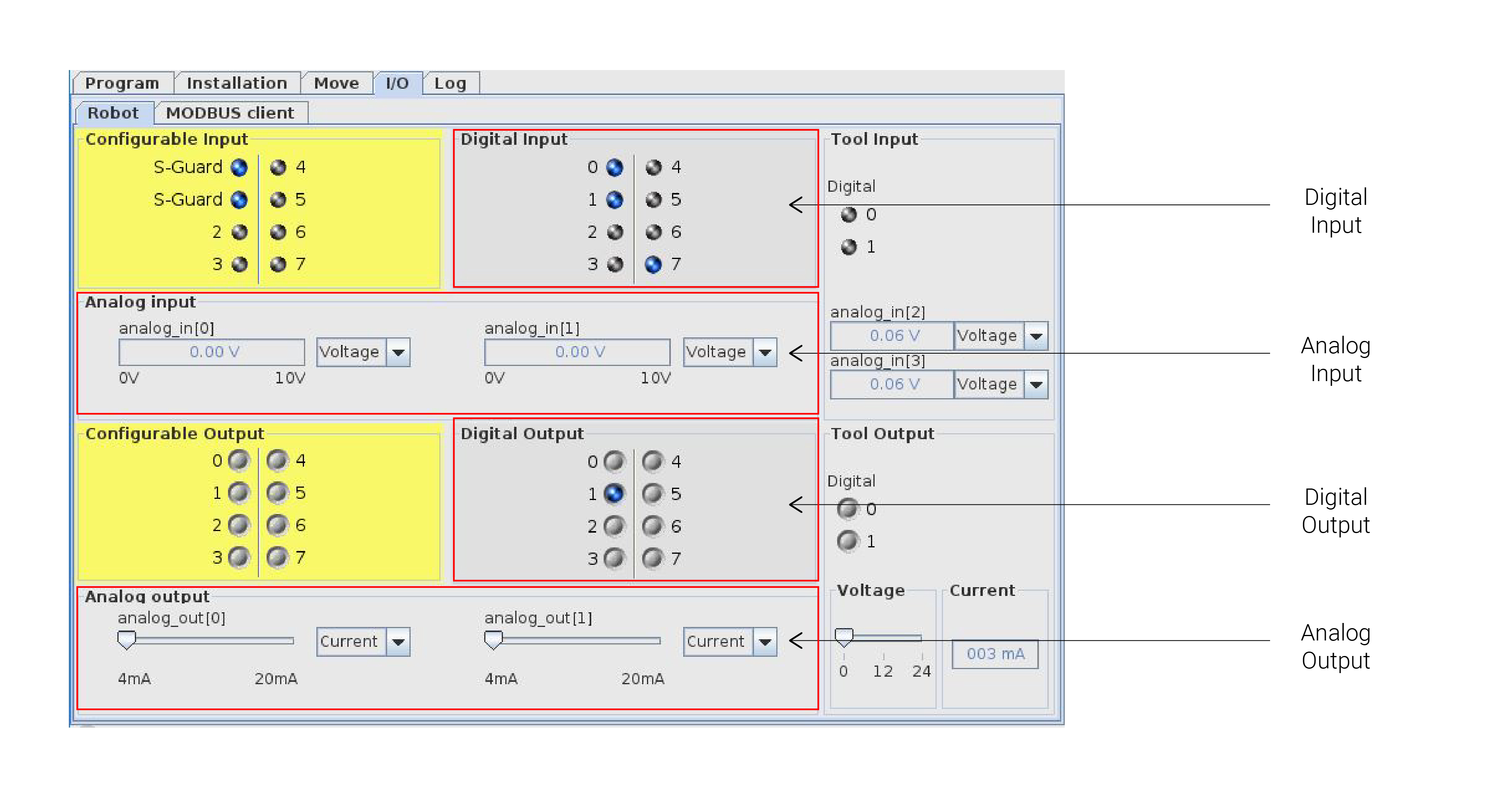

- I/O

- From flex pendant

- From code (commands)

Inputs and Outputs

- Robot have many pins for Inputs and Outputs:

- Write (Output)

- Digital (0,1)

- Analog (values)

- Read (Input)

- Digital (0,1)

- Analog (values)

- Write (Output)

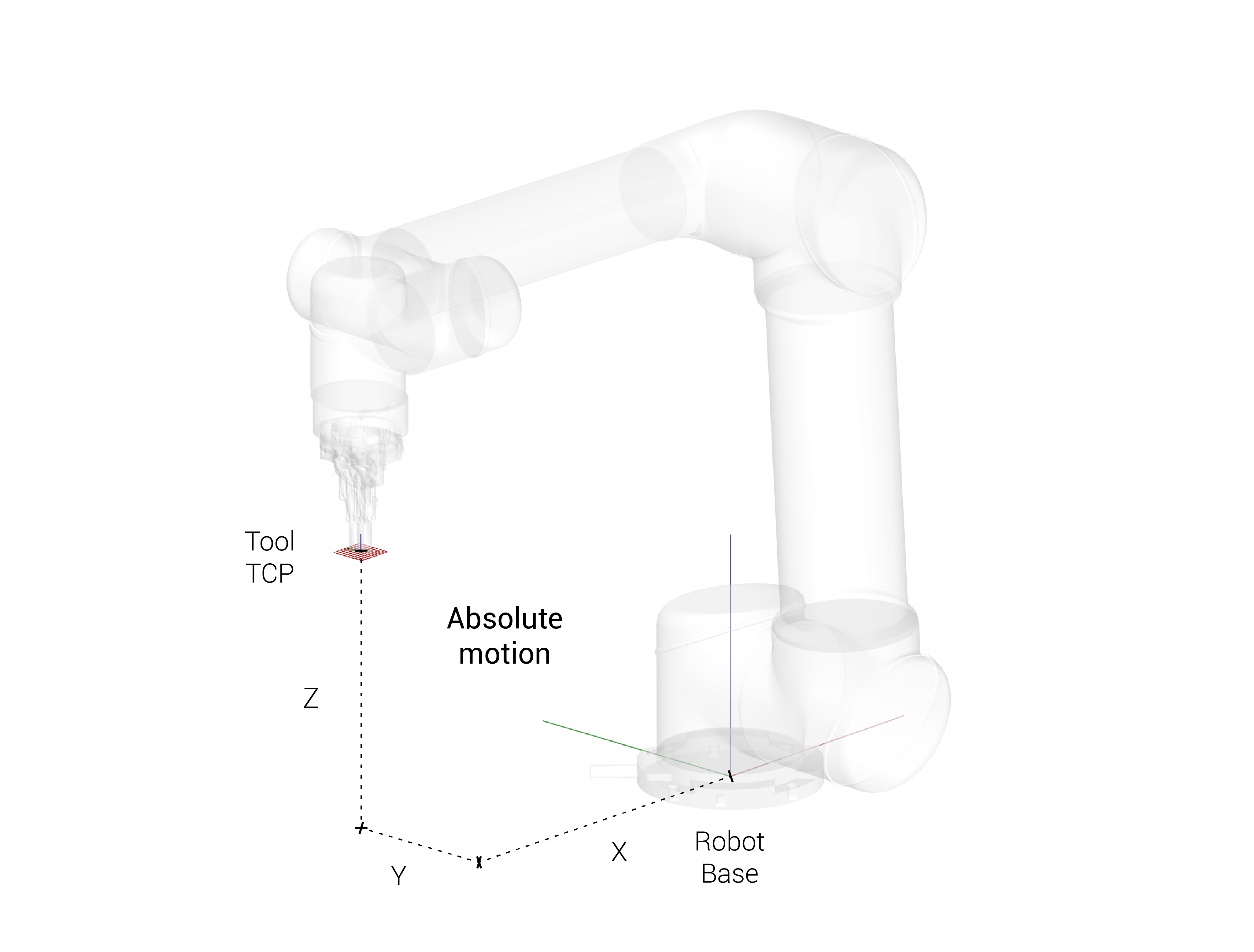

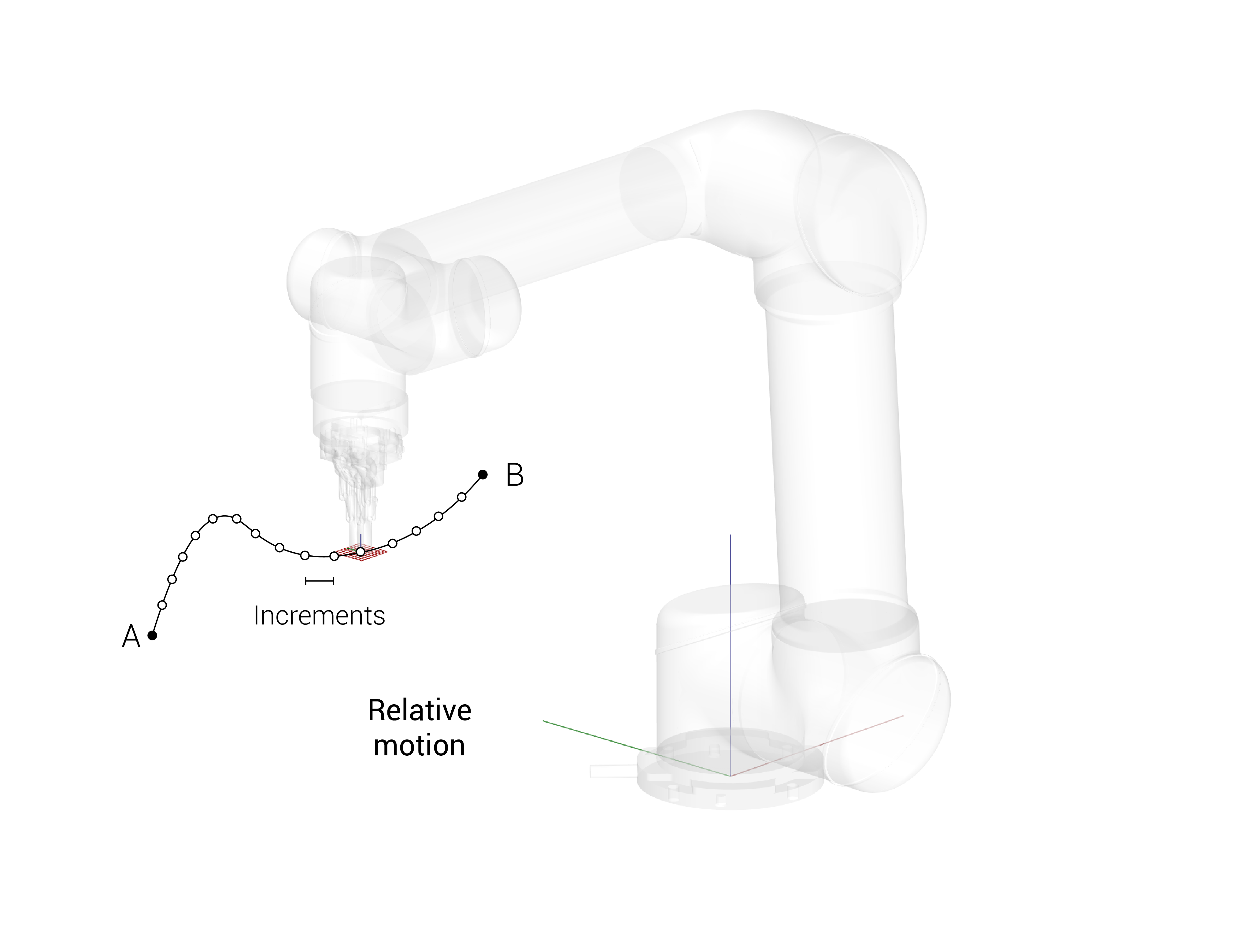

Relative and Absolute

Absolute position

Move anywhere in space based on the coordinate system of the robot

Relative position

Increments from wherever the robot was before in small steps

Speed

Absolute speed

Base speed

Relative speed

Incremented speed

Units

Millimeters per second (mm/s)

Precision

The robot never reaches the target that you have sent

radius = 0

radius > 0 (Blend radius in between trajectories)

Commands

List of command sequence (individual commands)

Block of actions

![]() Check: Robot reach

Check: Robot reach

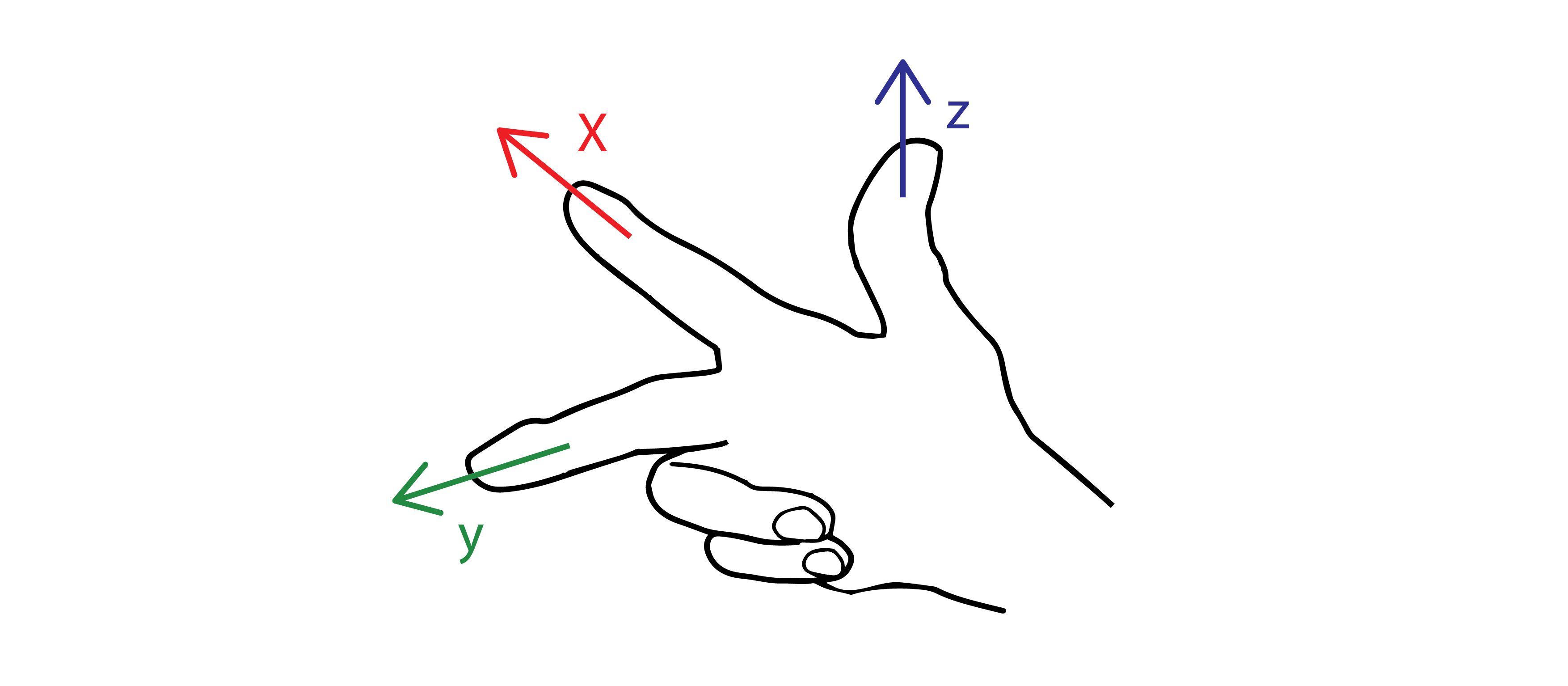

Rotations

Right hand rule

Absolute

From Base

Relative

From TPC

X (1,0,0) + angle

Y (0,1,0) + angle

Z (0,0,1) + angle

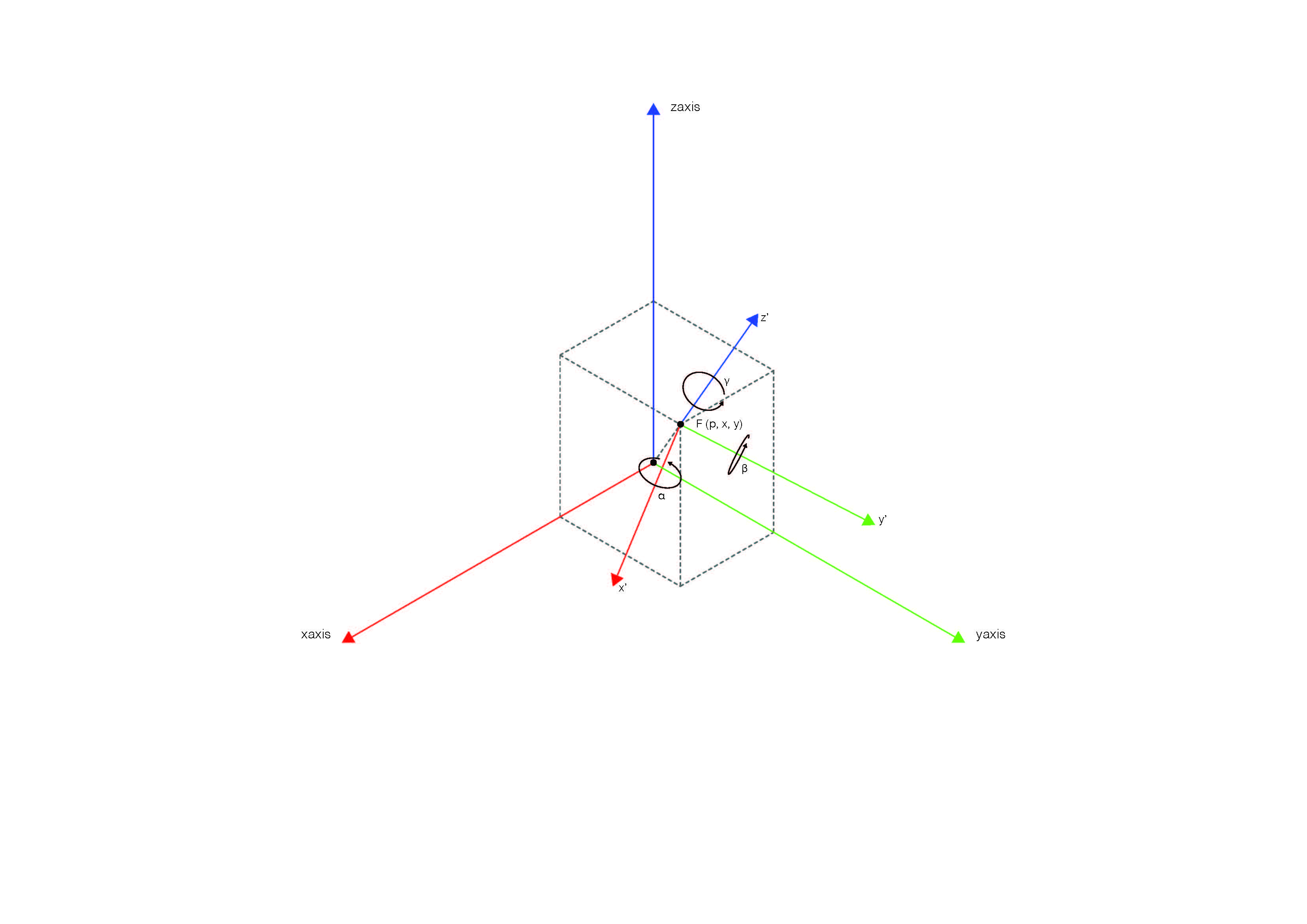

Motion and rotation

Changes position and orientation

pose = p[x,y,z,rx,ry,rz]

Example:

Position in base frame of:

- x = 200 mm

- y = 300 mm

- z = 500 mm

- rx = 0

- ry = 0

- rz = 180 deg

pose = p[0.2,0.3,0.5,0,0,3.14]

Frame transformation

Moving between targets

moveL

Move to position (linear in tool-space):

movel(pose, a=1.2, v=0.25, t=0, r=0)

Parameters

- pose: target pose (pose can also be specified as joint positions, then forward kinematics is used to calculate the corresponding pose)

- a: tool acceleration [m/s^2]

- v: tool speed [m/s]

- t: time [S]

- r: blend radius [m]

Example command:

movel(pose, a=1.2, v=0.25, t=0, r=0)

Example Parameters:

- pose = p[0.2,0.3,0.5,0,0,3.14] → position in base frame of x = 200 mm, y = 300 mm, z = 500 mm, rx = 0, ry = 0, rz = 180 deg

- a = 1.2 → acceleration of 1.2 m/s^2

- v = 0.25 → velocity of 250 mm/s

- t = 0 → the time (seconds) to make the move is not specified. If it were specified the command would ignore the a and v values.

- r = 0 → the blend radius is zero meters

moveJ

Move to position (linear in joint-space). The t parameter can be used to set the time for this move. Time setting has priority over speed and acceleration settings.

movej(q, a=1.4, v=1.05, t=0, r=0)

Parameters

- q: joint positions (q can also be specified as a pose, then inverse kinematics is used to calculate the corresponding joint positions)

- a: joint acceleration of leading axis [rad/s^2]

- v: joint speed of leading axis [rad/s] t: time [S]

- r: blend radius [m] If a blend radius is set, the robot arm trajectory will be modified to avoid the robot stopping at the point. However, if the blend region of this move overlaps with the blend radius of previous or following waypoints, this move will be skipped, and an ’Overlapping Blends’ warning message will be generated.

Example command:

movej([0,1.57,-1.57,3.14,-1.57,1.57], a=1.4, v=1.05, t=0, r=0)

Example Parameters:

- q = [0,1.57,-1.57,3.14,-1.57,1.57] → base is at 0 deg rotation, shoulder is at 90 deg rotation, elbow is at -90 deg rotation, wrist 1 is at 180 deg rotation, wrist 2 is at -90 deg rotation, wrist 3 is at 90 deg rotation. Note: joint positions (q can also be specified as a pose, then inverse kinematics is used to calculate the corresponding joint positions)

- a = 1.4 → acceleration is 1.4 rad/s/s

- v = 1.05 → velocity is 1.05 rad/s

- t = 0 → the time (seconds) to make move is not specified. If it were specified the command would ignore the a and v values.

- r = 0 → the blend radius is zero meters.

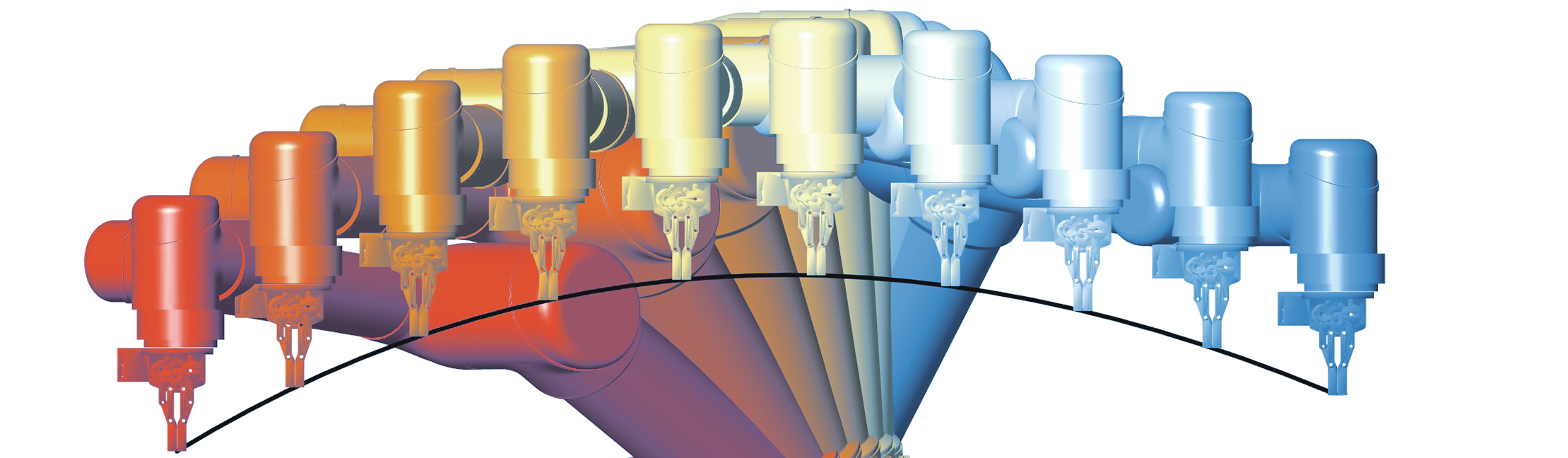

Axes

6 axes

- Base

- Shoulder

- Elbow

- Wrist 1

- Wrist 2

- Wrist 3

Kinematics

- Inverse

- Defined by pose coordinates

- Forward

- Defined angle value (joint position)

- Absolute Axes (0, -90, -90, -90, 90, 90)

- Relative Axes (10, 0, 0, 0, 0, 0) - Incremental